From "paper chaos" to intelligent quality assurance: How VDA standards are revolutionizing sampling

The future of quality assurance is digital: How can development time be shortened through more efficient QA? This technical article highlights the potential of standardized data formats (VDA 231-300/301) and shows the way from "paper chaos" to intelligent quality assurance in real time.

Sample Inspection (PPAP) under the microscope: Where do the hidden costs arise?

Why does sampling (PPF/VDA, PPAP/IATF) cost up to €9,000 per process? Causes, study results and digital solutions at a glance.

Ensuring sustainability right from the product development process: A paradigm shift for the manufacturing industry

The manufacturing industry is facing major changes with sustainability representing a significant challenge. Companies must increasingly address the reduction of toxic chemicals, greenhouse gas emissions, and the impending depletion of natural resources.

LkSG abolished - but the obligation remains: Digital evidence management for the EU CSDDD

The German LkSG has been abolished, but the EU CSDDD directive increases the requirements for human rights and environmentally compliant supply chains.

material.one links material data, parts lists and approvals across all levels, making it the central platform for digital verification management.

Supplemented by adesso's Scope 3 solutions, the result is a holistic system for CSDDD compliance and ESG management.

Another new VDA standard for digital material data management with support from material.one

New VDA recommendation 231-301 published

VDA 231-301 extends the existing recommendation 231-300 to include a standardized data model for the digital exchange of test results. The aim is to make quality assurance along the supply chain more efficient and traceable. material.one provided technical support during the development of the recommendation.

Press release: Strategic business development partnership between SNECI and material.one

Strategic business development partnership between SNECI and material.one. Expansion of business development and quality management in Europe and Asia

New white paper: How to protect your brand with proactive quality management

Increasing technical complexity and growing global supply networks increase the risk of recalls and jeopardize brand reputation. In this 12-page white paper, you will learn how you can achieve greater transparency, detect errors at an early stage and proactively ensure quality.

New white paper release: Securing supply chain processes in engineering

Prof. Dr. Martin Stirzel's white paper shows how multi-business networks and data ecosystems can support compliance management, verification and quality assurance at all levels of the supply chain. Prof. Dr. Stirzel sheds light on how business networks contribute to efficiency and compliance across all levels - from OEMs to downstream suppliers.

The curse of the obligation to provide proof - taming supply chains digitally

At the adesso Digital Day 2024, Jonas Rothe from material.one AG showed how companies can overcome the growing challenge of supply chain transparency. He discussed innovative approaches to ensure the necessary overview and security despite complex requirements and floods of data.

The integration of VDA 231-300 into DIN SPEC 91383

The integration of VDA 231-300 into DIN SPEC 91383 is driving the digitalization of the product engineering process (PEP). This standardization of data exchange in the automotive industry, supported by the JT data format, improves efficiency and product quality. Find out how this innovation is shaping the future of product development.

Magazine Article: On-time "start of production" with digital approval management

Efficient product development processes are crucial for a faster time-to-market. Traditional, analog approval processes hinder automotive manufacturers who are increasingly involving external suppliers. A continuous, innovative flow of information and the exchange of data within the supply chain can speed up these processes and reduce costs.

material.one at the ACHEMA 2024

At ACHEMA 2024 discover how material.one and adesso are shaping the future of the process industry! Find out how you can optimize your production processes and strengthen your competitiveness with innovative solutions. Get your free ticket now!

Intelligent standards: More than just PDF documents

How digital standards are revolutionizing the industry: Machine-readable, integratable, error-reducing and cost-saving; especially in the automotive industry.

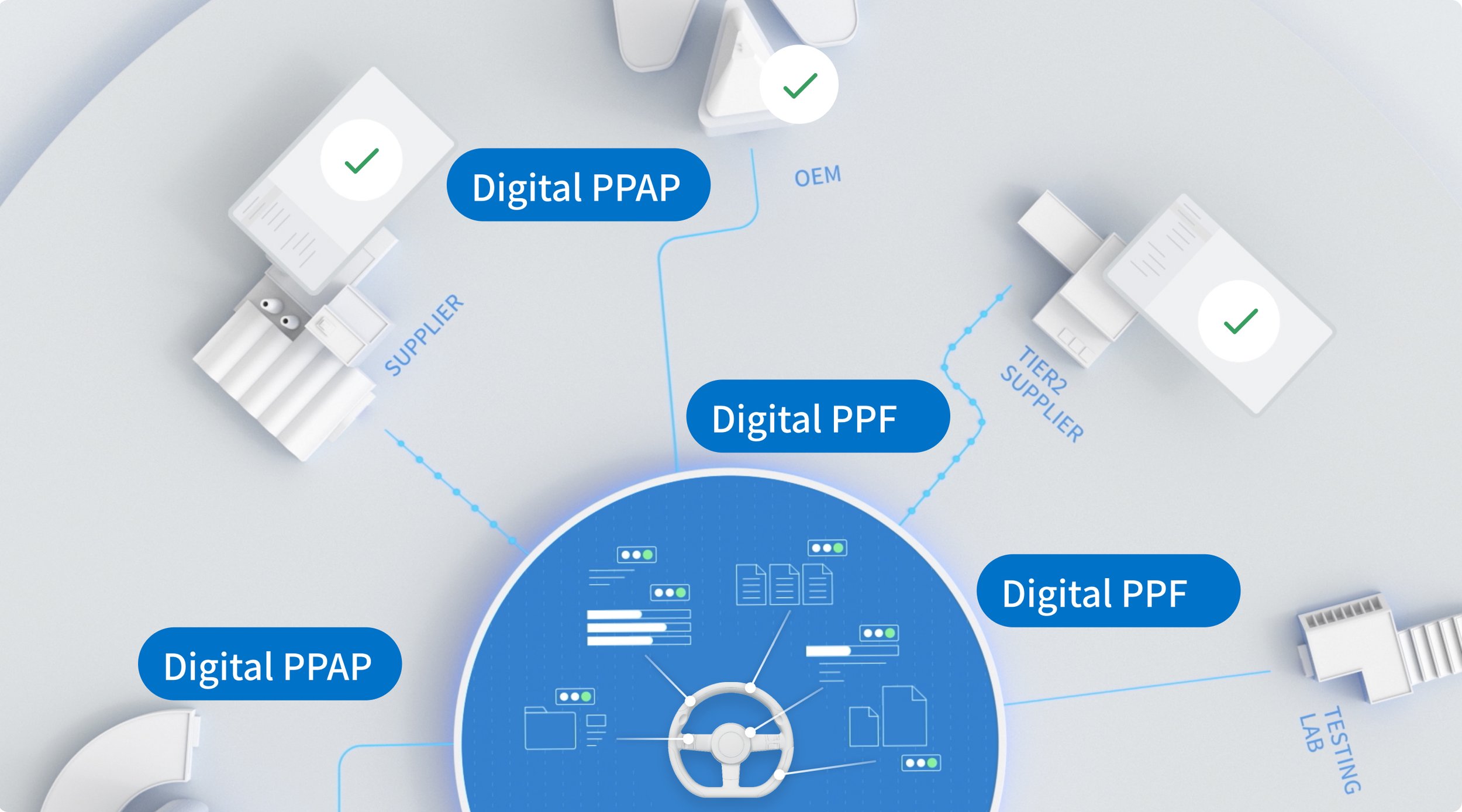

Collaborative approval & evidence management: How to Digitalize PPAP

Ben Rasoulkhani from material.one presented the Digital PPAP use case at the Automotive Masterminds Conference 2024 in Berlin. Ben highlighted its benefits in reducing quality issues and enhancing transparency. Their collaboration aims to improve efficiency and compliance in automotive manufacturing through ongoing platform development.

Digitization of the PPA (PPF) and PPAP process

This article provides an overview of the PPAP process and its practical application. The goal of PPAP to reduce risks before the release of products is greatly simplified and safer with Digital PPAP and a collaborative approach.

adesso and material.one: Strategic partners for the digital transformation of the automotive industry

Discover the future of the automotive industry at the Automotive Masterminds Conference 2024! We will discuss the impact of emerging players and strategic partnerships on product compliance and quality. We are present together with adesso SE as an exhibitor, sponsor and speaker. We are looking forward to valuable networking and insights.

Digital Product Passport: Opportunities and Challenges for Companies

The digital product passport drives green growth and helps achieve environmental and sustainability goals.

New standards promote sustainable production and supply chains in the automotive industry

New standards such as VDA 284 are driving the use of recycled plastics in the automotive industry. Together with initiatives such as DIN DKE's Circular Economy Roadmap and the digital platform material.one, they promote more sustainable production, accelerate certification processes, and contribute to the reduction of plastic waste.

Digitize production process and product approval (PPA) for series release

PPA is the release procedure according to VDA and stands for production process and product release for the start of series production. The article leads you to a solution approach to save costs and effort - and to become faster at the same time.

Secure Industry Cloud Platform - material.one passed its three year re-certified for the TISAX standard

material.one AG has again received TISAX certification for three years, which strengthens information security in automotive production and throughout the supply chain. This confirms that material.one meets high security standards in the supply chains between manufacturers, OEMs, and suppliers.

Jens Schmidtmann

Head of Corporate Communications