Digital Sampling

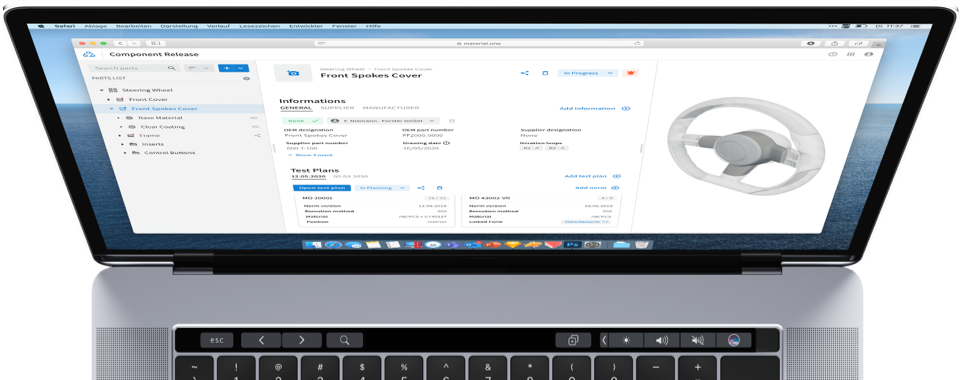

material.one unites manufacturers and suppliers as well as testing, inspection and certification providers on a single platform and digitizes the entire sampling process (PPAP/PPF).

"We simplify processes for manufacturers, suppliers and laboratories by minimizing manual effort and making FAI data available digitally ."

Bernd Löhle

CEO

Everything just flows

material.one supports you in every inspection phase

The 3D data is made available on the platform together with requirements from the OEM

1

The contracted laboratories run tests and enter the results into the platform

2

The supply chain creates test plans, commissions laboratories and collects the requested material information

3

The test results are automatically pre-assessed and released by the supplier to the manufacturer

4

The manufacturer inspects test results and decides if the component can be released

5

Inspection data is archived and can be used to optimize requirements

6

Test results recorded digitally on the platform

Live view of 3D models in-browser

Automatic generation of test plans

Smooth teamwork through task assignments

Tamper-proof test data

Automated quotation request (RFQ) from suitable laboratories

Reuse released data instead of re-inspection

Manufacturing standards are processed and made digitally available

Milestone tracking and transparent processes

Future oriented

Simplifying processes is just the beginning

One common platform creates trustworthy data

material.one digitizes the FAI process through the entire supply chain from the laboratories to the manufacturer. All information is shared directly over the platform. Every processing step is logged. This ensures that data is tamper-proof and traceable.

Efficient collaboration through uniform communication channels

Manufacturers, suppliers and laboratories communicate directly via the platform. All sampling data is easily and efficiently exchanged. Associated comments and attachments remain in the appropriate context and can be retrieved at any time.

Data analysis and transfer without manual processing

Because data is digitized, the formatting of inspection plans and forms is consistent. This means that information can be made available to all stakeholders without any special preparation or file conversion. Access is granted on a need-to-know basis.

Use data intelligently to optimize requirements

The valuable pool of inspection information from a wide range of components provides new opportunities for optimization. For example, analysis of inspection results allows material requirements to be adjusted resulting in reduced manufacturing costs or warranty claims.