Ensuring product compliance and quality through collaboration

Maximum transparency in meeting your product requirements and minimal compliance risks in your value chain. Enabled by digital requirements and evidence — from raw materials to end products and from product creation to the start of series production. material.one creates a digital twin of your components, whose data you can access anytime, anywhere.

"We simplify processes for manufacturers, suppliers and TIC (Test, Inspection, Certification) providers by minimizing manual work and making evidence of fulfilled requirements available digitally"

Jonas Rothe

Director Sales & Business Development

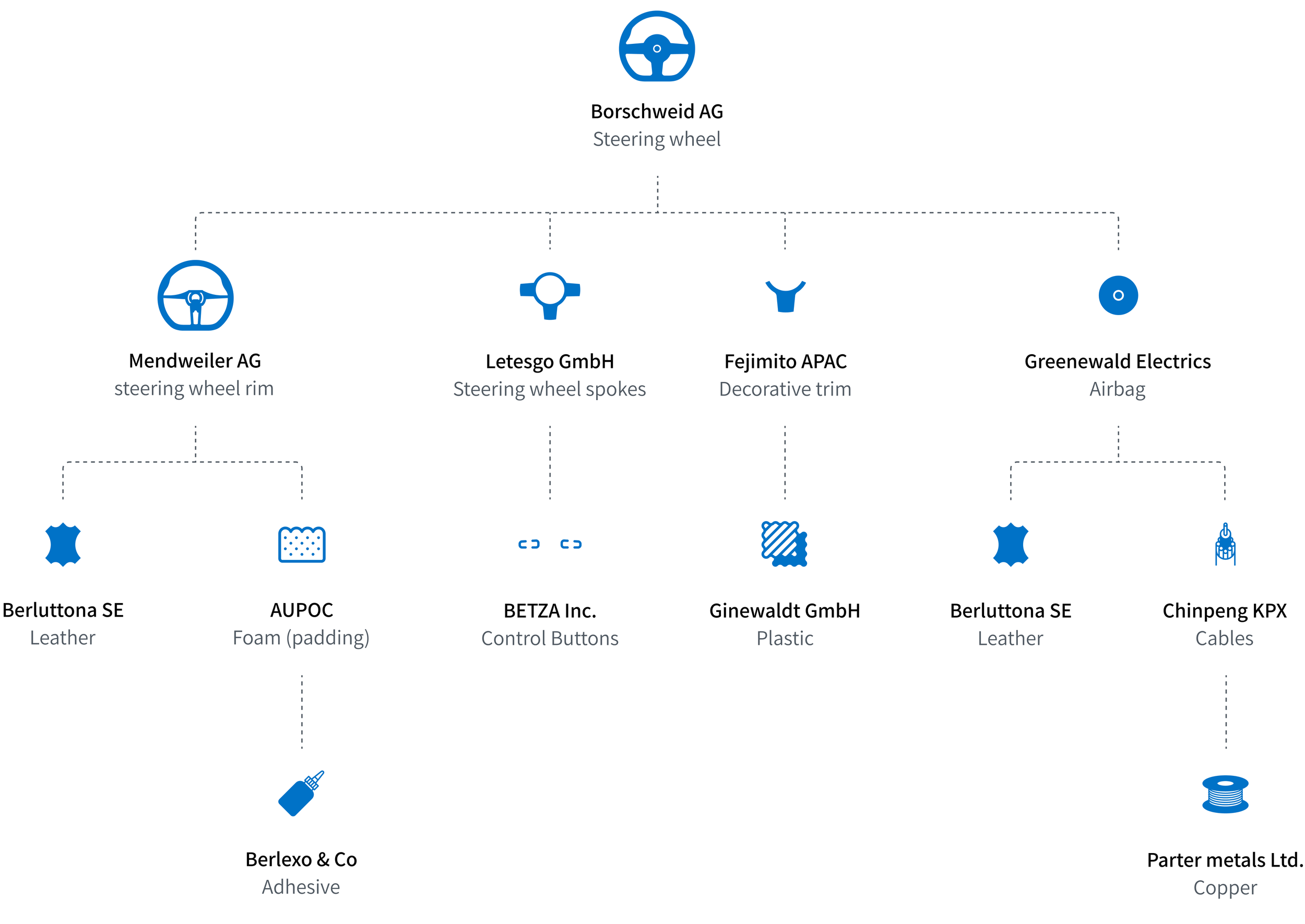

80% of components and materials do not come from the original manufacturer, but from global supply chains

Increasing customer demands force products to be more complex while the quest for ever more sustainable materials and production methods is compounds these demands. Companies face the challenge of maintaining high transparency - even down to the raw materials - despite complex supply chains and increasingly sophisticated products.

The challenges of collaboration for

modern supply chains

Weak data integrity

The use of PDF, Word and Excel files makes it almost impossible to determine the source of the data or to prevent content manipulation later.

Diffuse communication

Most manual peer-to-peer communication, like e-mail, creates delays and information gaps for workflow participants.

Complex data exchange

Data must be requested individually through each level and channel of the chain. This means that the required documents must be selected, sent, and then interpreted by the recipient for each request.

Our solution - interconnecting processes and collaboration

Clear communication

Networked communication via just one channel between all parties involved. Digital forms create clear requirements and clear answers.

Simplefied data exchange

Data is available to all stakeholders on a need-to-know basis. As soon as new data is available, it can be accessed at any time and from anywhere.

Greater data integrity

The platform serves as a Single Source of Truth (SSOT). No different versions or formats. Full transparency about the origin and author of the data.

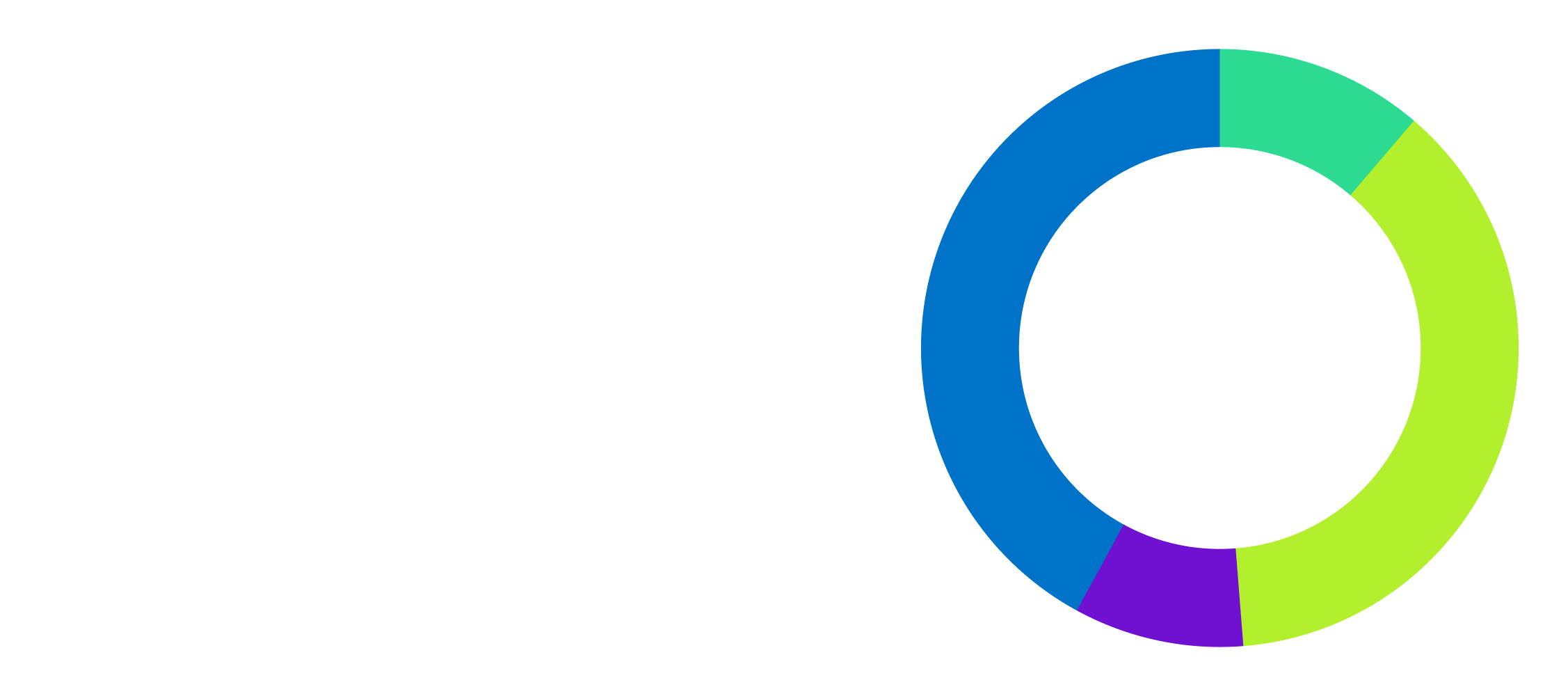

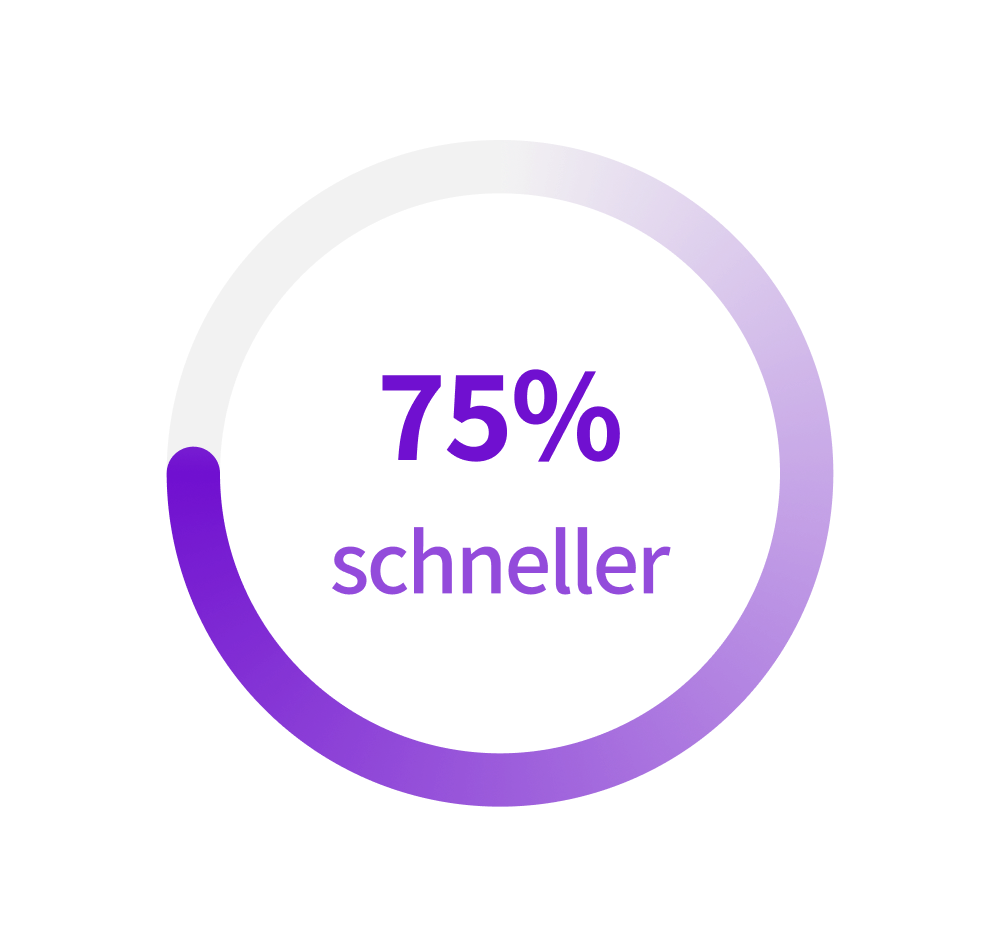

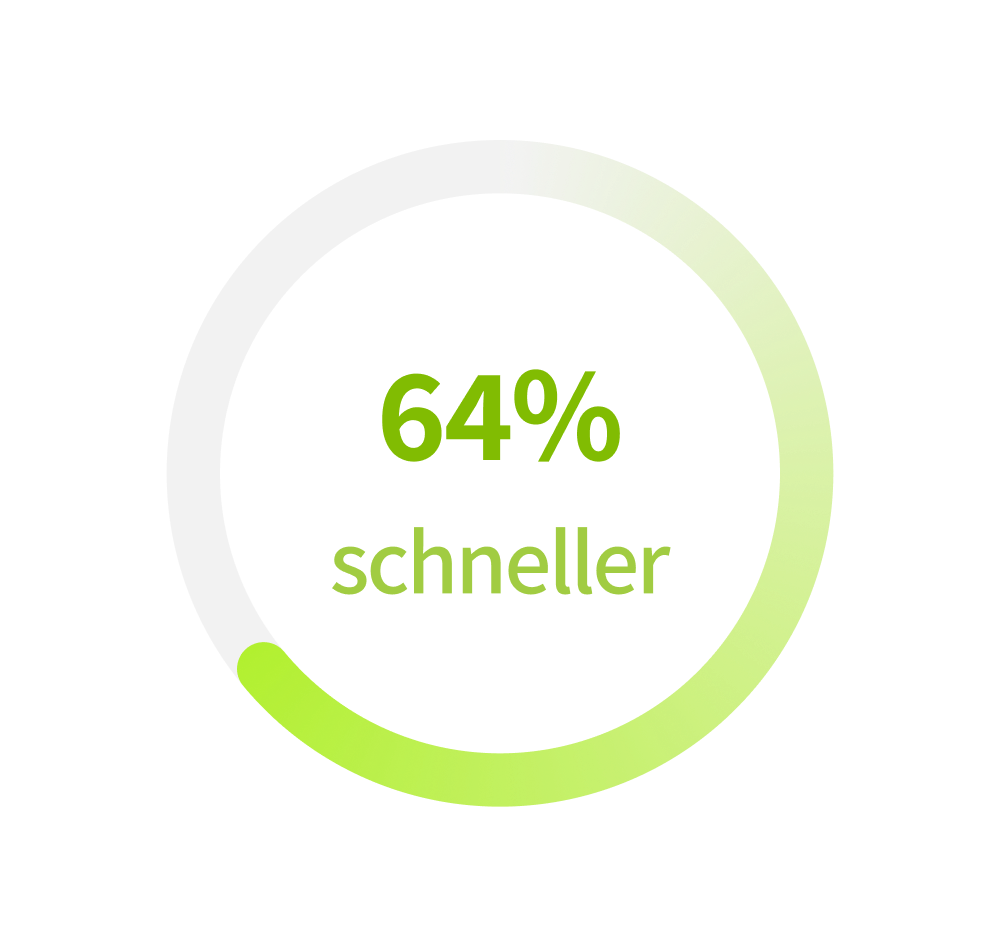

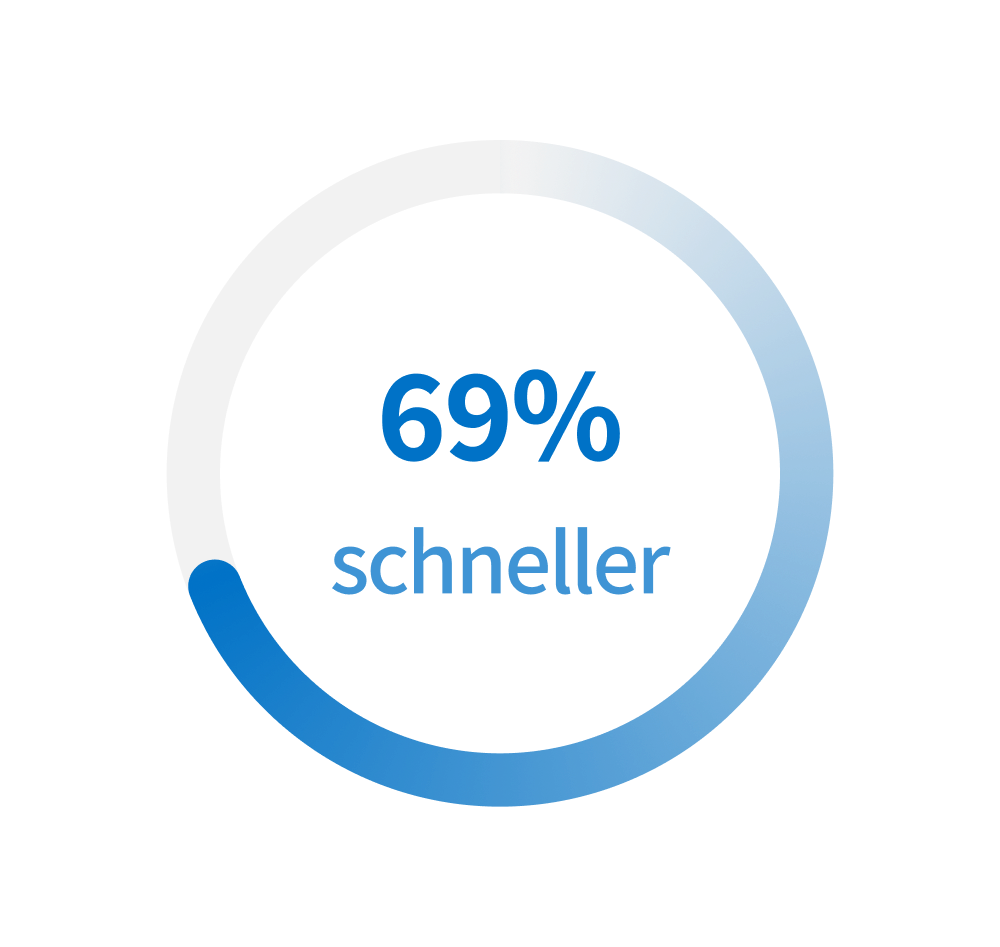

Reduce your effort

The results of the study "The potential of digital sampling" show the advantages of digital approval and evidence management

Effort with conventional

modes of operation

Effort reduced 64% with material.one

Source: Potentials of digital sampling, Prof. Dr. H. Tuczek, 2022

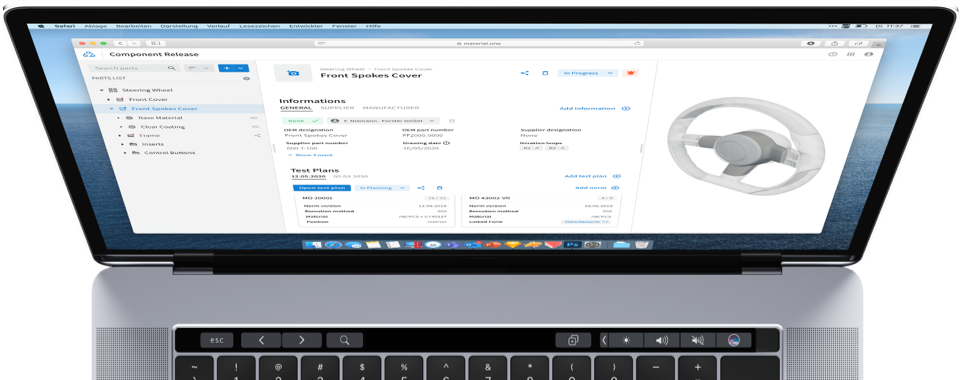

Match requirements

The coordination is done on the CAD model. The model is broken down down to the material level and the manufacturer's requirements are attached at each level. The digitalized requirements ensure that all specifications are up-to-date.

Record evidence of conformity

Digital capture ensures the integrity of the data. It is no longer necessary to open and interpret a multitude of different documents. In addition, APIs can be used to transfer test results from QMS and LIMS to the platform.

Plan proof of conformity

The digitalized requirements enable an automated inspection plan proposal. This ensures completeness. The inspection plans can then be shared with sub-suppliers. This balances the overall planning effort across the supply chain.

Evaluation and release

Inspection results are automatically compared to product requirements. This pre-assessment facilitates the evaluation of the conformity data. Data from the platform can then be transferred to the release systems (SAP, PLM).

Seamless integration

As a SaaS provider, we understand the challenges of implementing a new system that requires seamless integration with your existing workflows. material.one connects via API and data connectors to existing systems which do not reach deep into the supply chain - like PLM, ERP, PIM or QMS systems.

Solid technology

material.one uses Microsoft Azure. With material.one, our customers use a unique platform with customized features that is developed entirely in-house. Our platform is primarily hosted in the Western Europe region. This guarantees high availability and reliability of our services. As a customer, you also benefit from the industry-leading stability, reliability and maintainability of Microsoft Azure. At the same time, this optimizes business continuity and disaster recovery.

Data security and data protection

Security is a central component of our platform. First-class encryption and granular data access control guarantee greater security for your data. We are GDPR compliant, continuously monitor potential security threats and protect your data. To ensure geo-redundancy and maximize data protection, we store backups in the Northern Europe region. This approach ensures that data can be restored safely and quickly even in the event of a regional outage in Western Europe.

Benefit from the advantages of digital verification

SMART CIRCULAR ECONOMY

Demonstrate compliance to environmental requirements

Take advantage of new opportunities to reliably demonstrate conformity to environmental requirements and key performance indicators. Suitable for GHG, Scope 3, toxic and hazardous substances or for the determination and verification of recycled content.

SMART PRODUCT APPROVAL

Digital FAI

Simplify the verification process in the product creation process (PPAP/PPF). Evidence of conformity to standards and laws as well as information on the component and materials are available anytime, anywhere and for everyone.

SMART STANDARDS

Digitize requirements

Machine-readable standards are the basis for automated processes from the creation of test plans to the evaluation of test results. No more room for interpretation when meeting your standards.