We digitize workflows for manufacturers

With decreasing vertical integration, manufacturers must rely more than ever on supply chain data to guarantee product-series delivery in time for SOP.

Future oriented

Simplifying processes is just the beginning

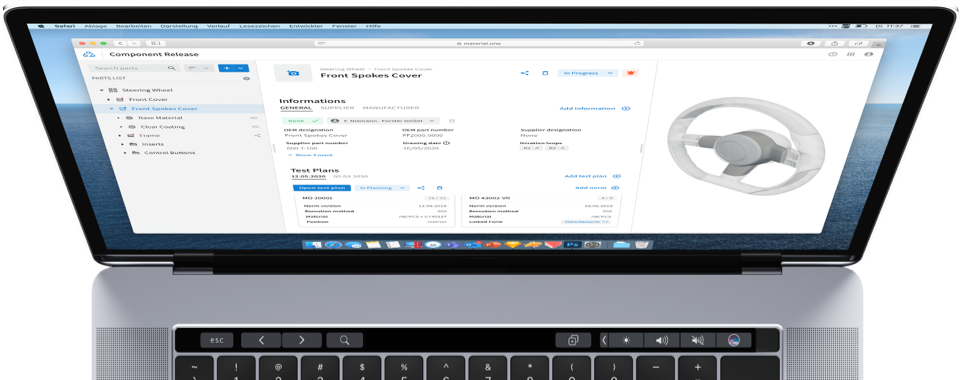

Process requirements digitally

material.one converts, for example, standards catalogs and delivery specifications into a digital form so that the information can be further processed. The digitized creation of test plans is thus associated with a significantly lower workload. At the same time, standards and regulations can be updated and optimized.

Ensure quality in the laboratory reliably

For particularly important tests, suppliers can only work with a specific list of approved laboratories. Material.one helps to ensure that these laboratories provide the required quality certifications at regular intervals, that deadlines are being met and further oversees the administration of certificates.

Collaborate more effectively with suppliers and laboratories

material.one offers manufacturers a platform where material-specific information can be exchanged with suppliers and laboratories, data is shared directly, test plans are created, and forms filled out digitally. Consequently, communication among stakeholders is improved significantly.

Handling the digitization of requirements in a cost-saving way

Taking the example of initial sampling of materials and components, this is associated with very high costs for the manufacturer. Material.one digitizes the test chain, standards and test specifications so that labor-intensive processes are now automated, which in turn leads to significant cost savings.

SMART STANDARDS

Digitize requirements

Machine-readable standards are the basis for automated processes. From creating the test plan to evaluating the test results.

SMART PRODUCT APPROVAL

Digital FAI

Simplify the verification of standards, laws, and component and material information (PPAP/PPF).

SMART CIRCULAR ECONOMY

Demonstrate compliance to environmental requirements

Take advantage of new opportunities to reliably demonstrate conformity to environmental requirements and key performance indicators.