Ensuring sustainability right from the product development process: A paradigm shift for the manufacturing industry

Green engineering - sustainable product development

The manufacturing industry is facing significant changes with sustainability being key among them. Companies must increasingly reduce toxic chemicals and greenhouse gas emissions as well as counteract the threat of depleting natural resources.

The sustainable approach in the manufacturing industry begins in the product development process (PD Process) where companies aim to meet or exceed sustainability requirements. This creates a balance between economic growth and environmental protection, gives the brand a progressive character, and inspires customers.

But what exactly is sustainable product development? The aim is to make products environmentally friendly, socially responsible and economically viable in order to meet the requirements of current and future generations.

Various approaches can be used in the manufacturing industry for sustainable product development

1. energy efficiency: Products should be energy-efficient in order to help reduce the industry's carbon footprint.

2. longevity of products: Products should be designed to last as long as possible to reduce the need for being replaced and minimize the environmental impact of scrap.

3. recyclability: products should be easy to recycle and reuse by using recyclable materials, being easy to disassemble, and reducing the use of toxic chemicals.

4. life cycle analysis: The entire life cycle of a product should be considered; from the procurement of raw materials to disposal at the end of life in order to reduce environmental impact.

5. social equity in the supply chain: Suppliers should adhere to ethical and sustainable principles such as fair working conditions and environmentally sound procurement of raw materials.

The application of green design practices and digital product and material approval processes can help companies reduce costs, improve product quality and strengthen their brand image.

Integrating sustainability into the PD Proces starts with understanding the product requirements and the type of use. It is crucial to understand environmental impacts in the PD Process, including resource and energy consumption, waste generation, and CO2 emissions.

At the end of the product life cycle, it is important that products meet safety standards and comply with legal requirements, including the removal of hazardous substances before disposal.

The sustainable supply chain as a key element in the PD Process

OEM sustainability requirements for their suppliers and their evidence from the various levels of the supply chain for maximum transparency and security

The supply chain plays a central role in the PD Process as over 80% of supplier products originate from the supply chain. This requires an increased transfer of requirements and corresponding proof of conformity. To meet these challenges processes must be digitalized and new tools integrated into existing processes.

Prepared today for the requirements of tomorrow

The supply chain collaboration platform material.one provides manufacturers and suppliers with a digital standard for data exchange in the supply chain. It enables direct access to supply chain information and a rapid response to future requirements. material.one standardizes the digital exchange of data and ensures optimal verification of conformity to environmental requirements.

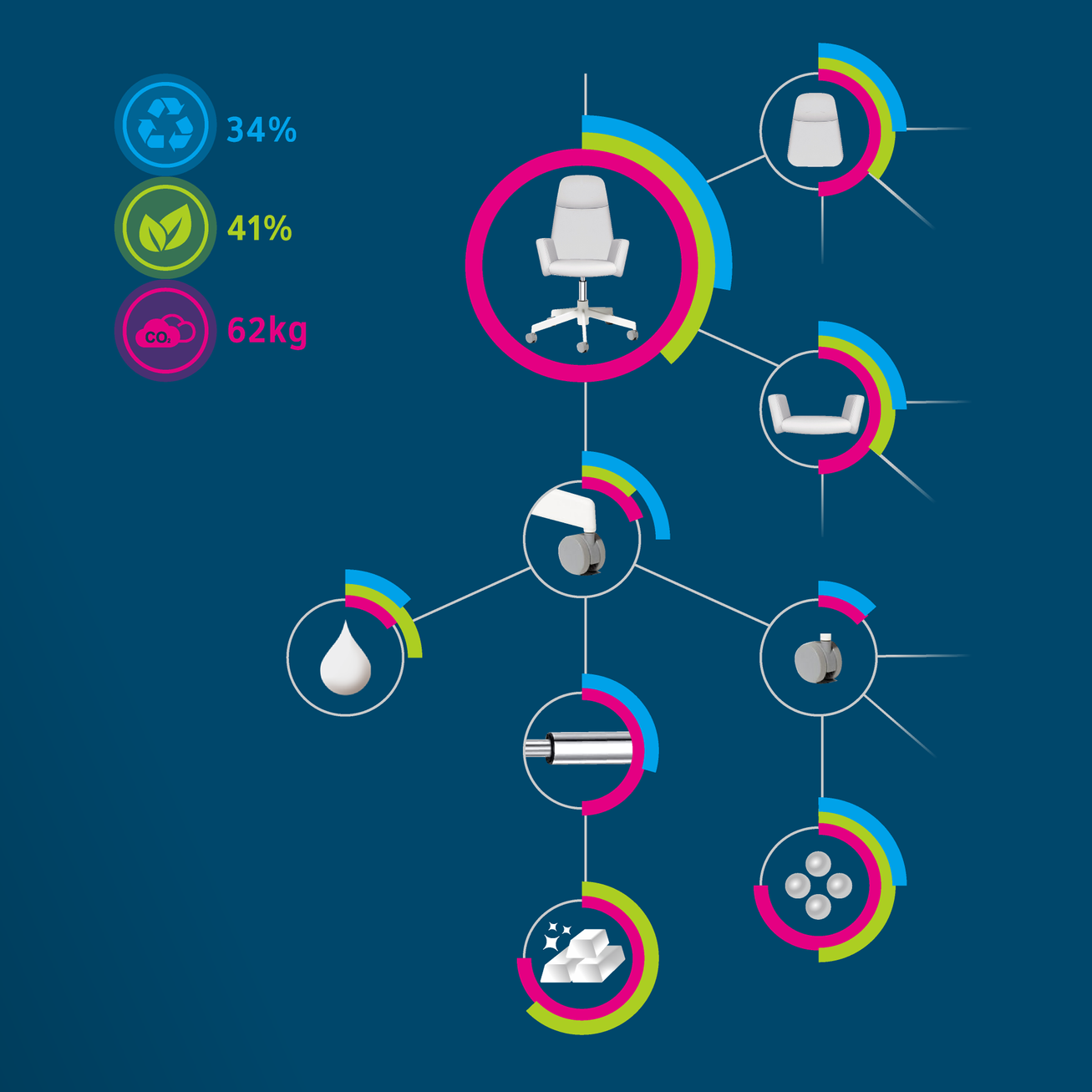

The platform provides insights into environmental indicators, material and product data from the supply chain at the component level (bill of materials). It creates a digital twin of the product with these indicators in order to intelligently optimize environmental requirements.

Conclusion

Integrating sustainability goals into the product development process offers the manufacturing industry an opportunity to reduce environmental impact, become more efficient, and be successful in the long term. Companies can not only assume their responsibility for the environment, but also benefit from the economic advantages of an environmentally conscious product development process. A digital, networked, and transparent supply chain plays a crucial role in this endeavor and material.one offers the necessary functions for maximum transparency, time and cost savings, and improved product conformity.

Read more articles

Our articles offer quality, production and laboratory managers valuable insights to successfully drive the digital transformation within their companies.

Learn more about material.one

With material.one all stakeholders can collaborate a standardized manner in a compliance conforming way based on the "need to know". As an industry cloud platform, material.one provides information on material and material sampling, percentage of recycled material, certificates as well as CO₂ footprint information.