Digitize production process and product approval (PPA) for series release

PPA is the release procedure according to VDA and stands for production process and product approval for the start of series production

Up to 80% of parts and components in the manufacturing industry come from the global supply chain. At the start of production (SoP) at the OEM (Original Equipment Manufacturer), all required parts must meet the requirements specified in standards, directives, and laws in order to receive series approval. Due to increasing legal requirements and the high complexity of the supply network, this represents a major challenge for manufacturers. Reliable planning is required for a smooth SoP. In the automotive industry, for example, automotive core tools have been established as planning instruments specifically for this purpose. One component of this is the production process and product approval (PPA or sometimes abbreviated PPF) for the series release of supplier parts.

Many components and products are also procured from different parts of the world in sectors similar to the automotive industry such as the electrical, aviation and transportation industries (rail, shipbuilding, logistics technology, etc.). For this reason, many processes in these industries are based on the standards of the automotive industry.

This article provides a comprehensive overview of the PPA process and how digital sampling can be used to make processes simpler and more secure.

What is PPA? Definition of production process and product release

The PPA process according to VDA describes the release of products and production processes for series production by the customer. In this approval process the legal requirements, quality guidelines and product specific requirements for the parts must be fulfilled. For the release, "PPA samples", also known as initial samples, are produced and evaluated under series production conditions. The central element of the PPA is the First Article Inspection report (FAI). This documents all important data on requirements and test results. The initiator of the PPA process and the release of series production is the OEM. Within the supply chain the obligation to provide evidence applies not only to the supplier, but also to the sub-suppliers. The production process and product releases for a part or component within a supply chain are part of the PPA document.

Importance of PPA in the industry

The PPA process is part of the product development plan (PD Plan). This plan includes all the steps required to develop a new product or to improve an existing product. The PPA process in the PD process is intended to ensure that the end product meets the requirements in series production. Compliance with these requirements leads to high product quality and satisfied end customers who ideally recommend the manufacturer to others. This is why the PPA concept is used in sectors with particularly high safety and quality requirements such as the automotive, aviation, food and pharmaceutical industries. The supplier only receives approval for series delivery if they successfully demonstrate a secure manufacturing processes and that the required properties of the component can be guaranteed.

Source. DGQ

Areas of application of the PPA process

The German Association of the Automotive Industry (VDA) describes the requirements for the quality of components or assemblies in its Volume 2 "Assuring the quality of deliveries". This publication contains a description of the procedures for production process and product approval. In Germany, the customer-specific requirements of the automotive industry are defined in consultation with its customers. These guidelines apply between the OEM and the organization, but also for sub-suppliers. The sixth edition of VDA Volume 2 was published in 2020. It contains some innovations such as the integration of software to optimize the joint work of all parties involved. In addition, VDA Volume 2 requires FAI to be adapted to new standards and laws, such as the Act on Corporate Due Diligence Obligations in Supply Chains and the Digital product passport.

The PPA process is used by the majority of German automotive companies. According to the American working group for supplier quality requirements(AIAG = Automotive Industry Action Group), series production is approved in accordance with the Production Part Approval Process (PPAP). Both approval processes are similar in many respects.

In addition, the minimum requirements of ISO 9001 apply to the supplier's QMS for production process and product approval. This is an internationally recognized standard that defines quality management systems and specifies their requirements. The measures required by ISO 9001 form the necessary basis for meeting customer requirements and other requirements for product and service quality. It is relevant for companies that want to prove that their products or services meet their customers' requirements and continuously improve the quality of their products or services.

In the automotive industry, the IATF 16949 quality management system standard is also used to define the basic requirements for quality management systems for series and spare parts production. This is not an independent standard, but an innovative supplement to ISO 9001.

Coordination of sampling - the sampling meeting

According to VDA Volume 2, the sampling process must be agreed with the customer in accordance with Chapter 5 "Planning and Agreeing the PPA process". As part of the coordination a determination on when and in what form the required data, documents and sample parts must be available to the customer on a project-specific basis. In accordance with the VDA, maturity level assurance (MLA) or advanced product quality planning (APQP) are used as planning criteria. This gives the supplier greater responsibility for the agreements on the PPA process.

The PPA process can only be successfully implemented if the efficiency of the production process has been proven. For this purpose, the product and process key figures for the statistical review are defined in the sampling meeting. VDA Volume 2 Annex 2 contains a list of the points required for the coordination of suppliers. This process step must be documented and attached to the PPA report. If a component is produced at different locations, production sites or in different manufacturing processes, a separate PPA procedure must be carried out for each variant. The supplier must coordinate the following verifications with the OEM:

Product development - production process development

Initial sampling and product testing

Documentation of the production process

Software

General suitability, such as compliance with legal requirements and suitability of test equipment

If components are reused, modified or supplemented, the previous PPA documents can be referenced.

Importance of material data in the PPA process

With increasing sustainability requirements the importance of the materials used is growing. For many years now product components have been listed in the material data sheet. The international material data management system (IMDS) is used to document material data throughout the production chain. Based on the IMDS, a material data sheet is created for the respective component, which contains all materials, material components, and subsequent recycling processes. The IMDS-ID-NR is used as proof for the PPA process. When selecting materials, suppliers must pay attention to prohibited and declarable substances in accordance with the "Global Automotive Declarable Substance List (GADSL)". In addition to the technical and IMDS data, more stringent requirements are now placed on the selection of materials, such as:

Low CO₂ footprint during production

No emission of harmful substances from the product

High proportion of recycled material

Compliance with human rights during extraction and production in accordance with the Supply Chain Due Diligence Act.

Compliance with legal regulations and customer requirements must be taken into account right from the start of development. This applies to the combination of material and manufacturing process.

Procedure of the PPA process

For the PPA process to be successful, all parties involved must...

-

o At the start of the PD process, the requirements for the component must be agreed upon between the manufacturer and the customer. This also applies to sub-suppliers in the supply chain

-

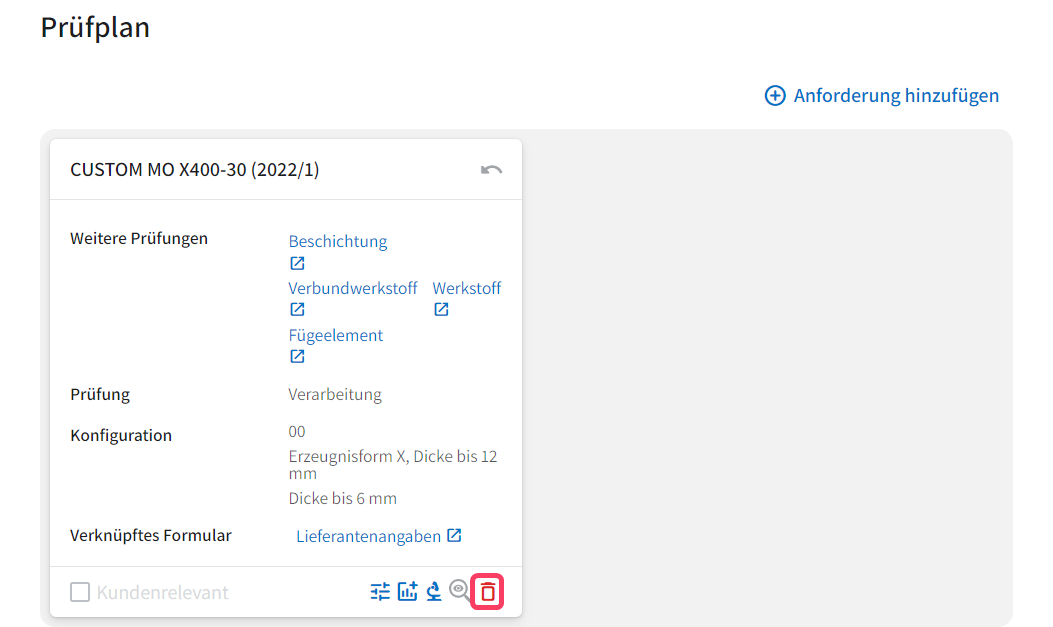

A test plan is drawn up based on the customer's requirements. All standard requirements and test specifications must be compiled with for this purpose.

-

After test production under series conditions, samples are taken and labeled. The results of all tests are compiled in the FAI report. In addition, all material and process-related data must be prepared by the manufacturer.

-

The test reports of the initial samples are evaluated and then submitted to the customer. In addition, the samples taken are sent to the customer. After reviewing the documents, the organization decides on the release for series delivery.

-

If deviations from the requirements occur during the development process, these must be clarified with the organization in advance. If the release of a deviation is approved, this must also be documented in the PPA.

Requalification in the PPA procedure

Through requalification, the supplier proves the stability of series production to the customer. According to VDA guidelines, the framework conditions for this should be defined during the coordination process. The customer does not always specify how often requalification must be carried out by the organization. In this case, an annual inspection is usually recommended. The customer's component specifications, as stated in the initial sample test report, apply to requalification. The customer must be notified immediately of any deviations during requalification. The following documentation is required for requalification:

Cover sheet

Evidence of dimensional and functional tests

Factory certificate or test report on the material properties

Requalification can be carried out as part of product audits in accordance with IATF 16949. VDA Volume 6.4 describes the exact implementation and the distinction between product audits and requalification.

Advantages of using digitized PPA processes

The PPA procedure requires a great deal of time from specialized staff for documentation. In addition, manual processing can lead to errors when transferring data. As part of continuous improvement, it is worthwhile for manufacturers to digitalize the PPA process end-to-end.

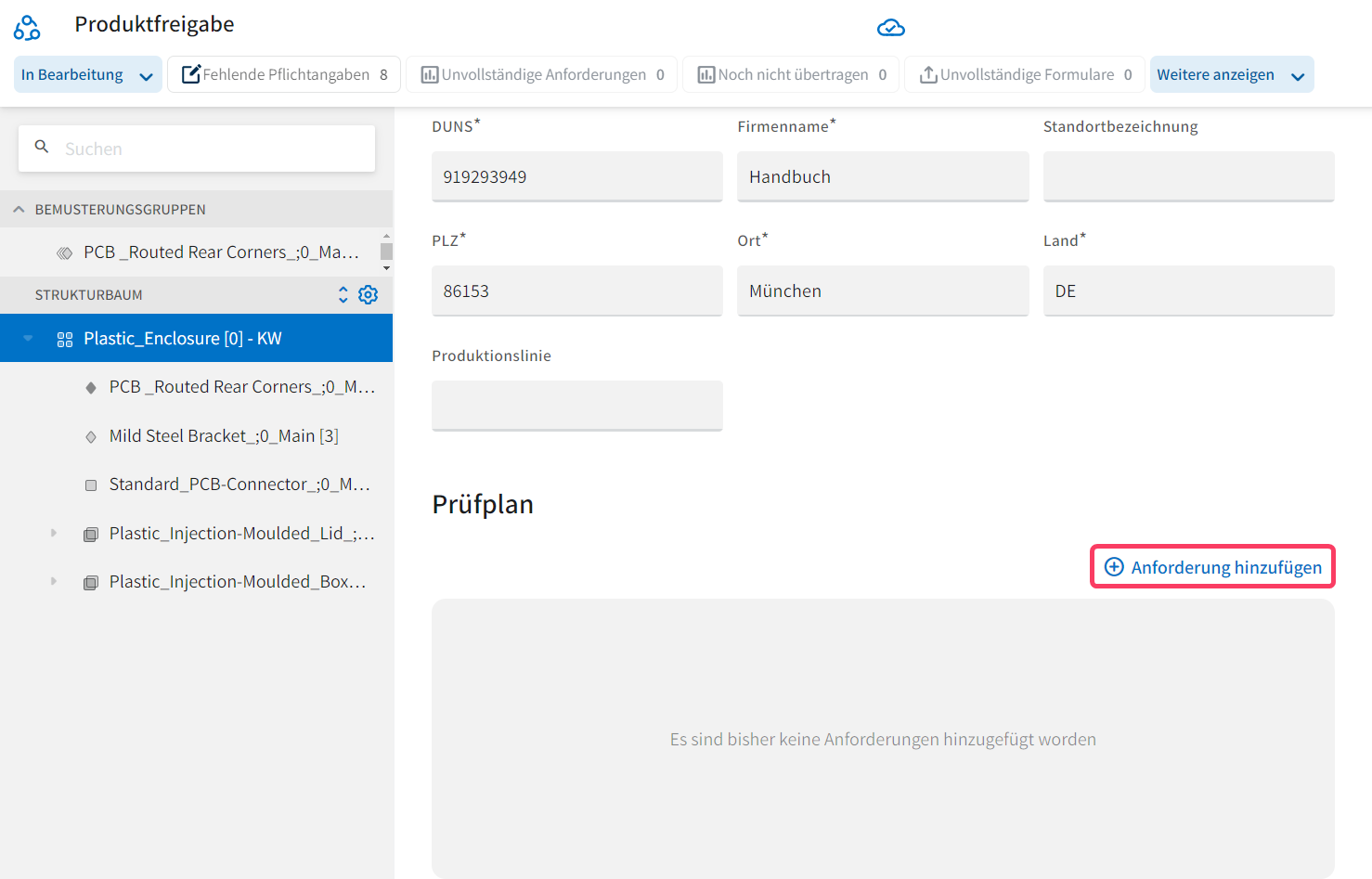

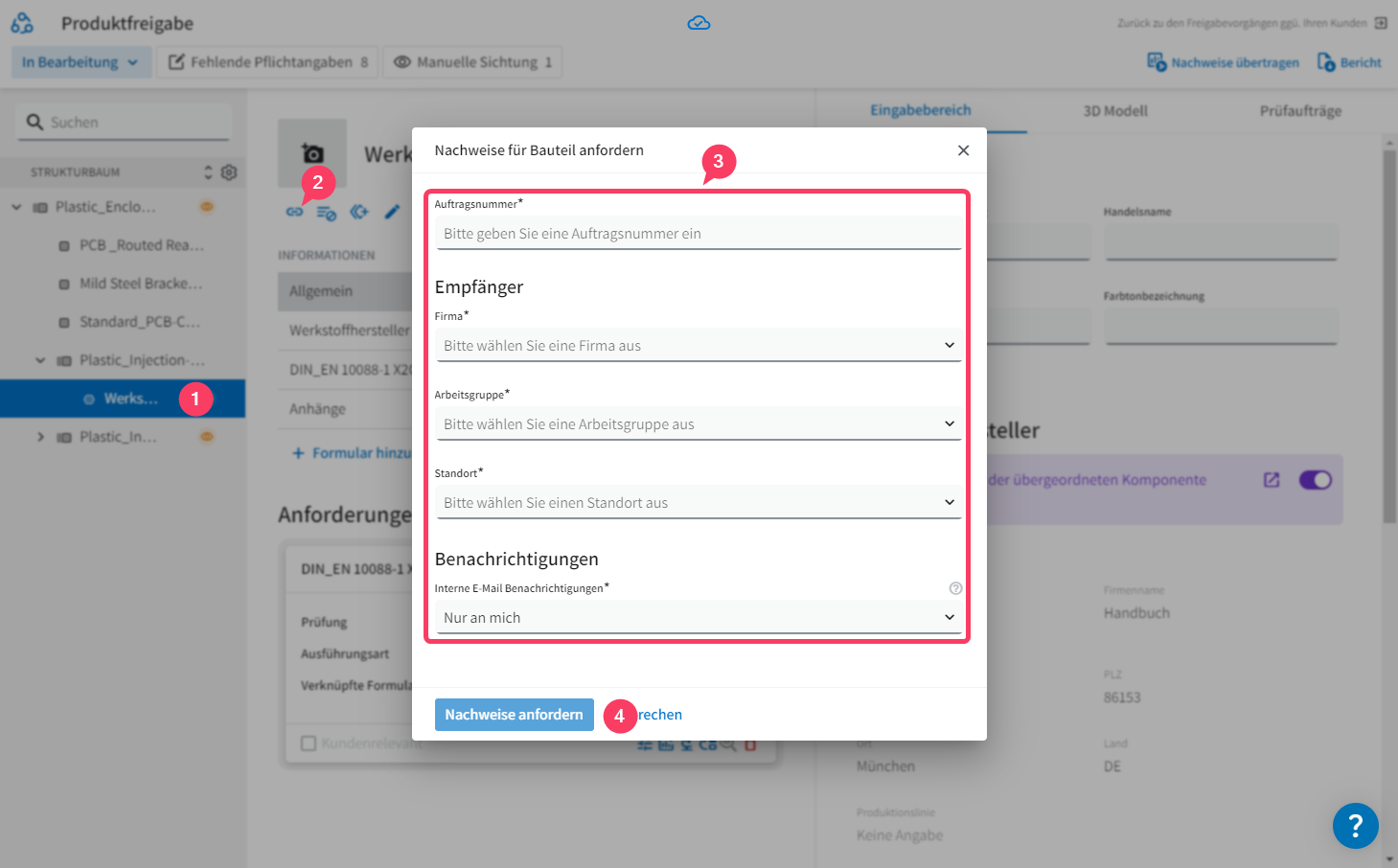

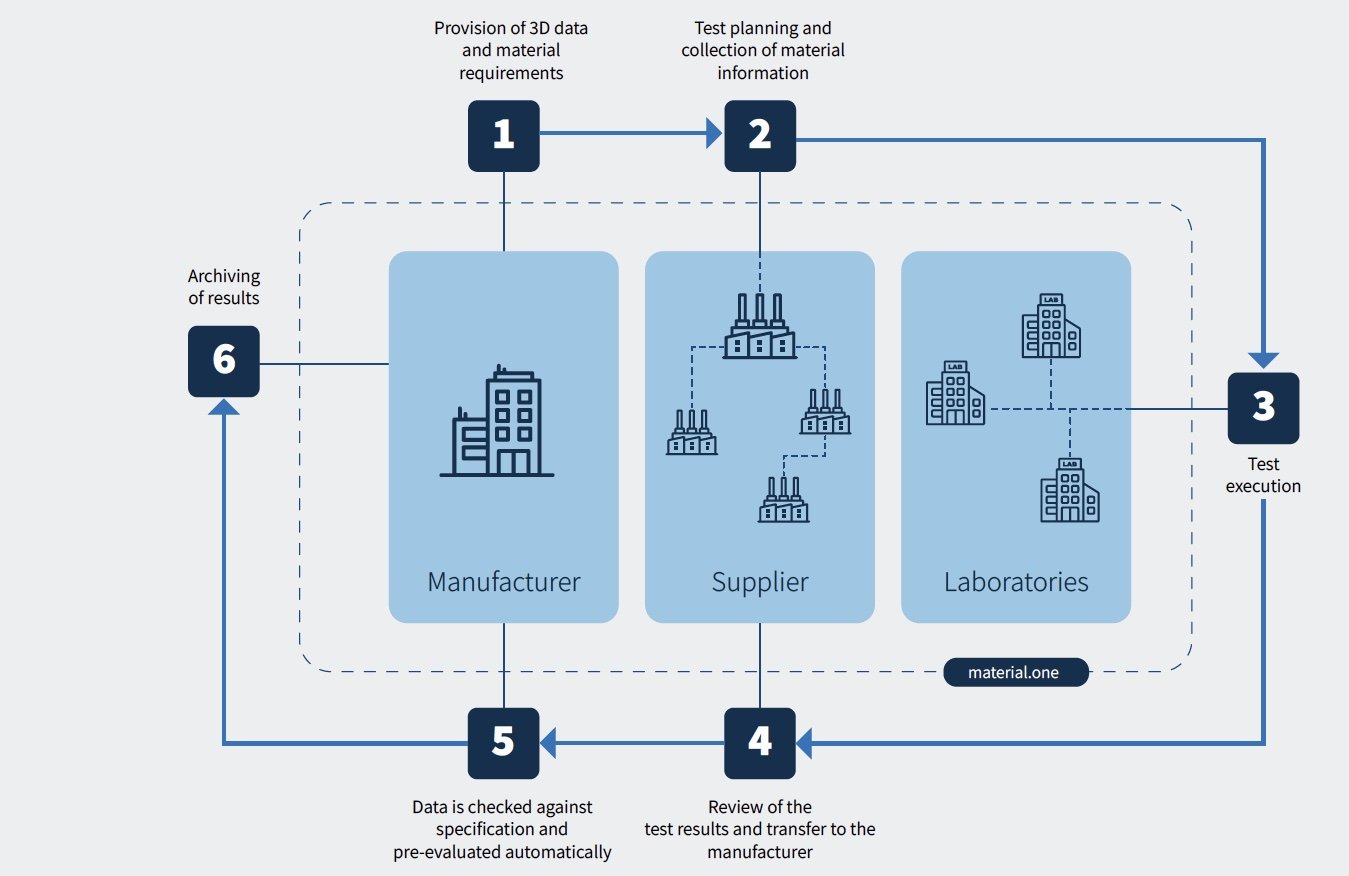

This is precisely where material.one AG comes in with its Industry Cloud Platform. This cloud platform, known as a "Supply Chain Collaboration Platform" in technical jargon, makes material sampling significantly simpler and more secure. The required material data and tests are managed and provided during the product development process.

The platform enables the CAD model to be extracted with the associated requirements profile for the part or component. At the same time, the system provides access to the legal and company's own test standards. The standards and environmental requirements are digitized and made machine-readable. Starting in the concept phase, the properties of the materials can be checked for compliance with the standard requirements; for example environmental compatibility. Based on the data from the manufacturer using material.one, the material.one cloud platform creates a draft test plan. A selection of available laboratories is listed and commissioned directly by the system after approval.

CAD data, product requirements and inspection plans for sub-suppliers can also be provided. material.one dissolves existing process and company boundaries and transfers these processes seamlessly into the supply network.

material.one eliminates many time-consuming manual steps, such as error-prone collaboration based on different document types and uncoordinated email communication. The platform greatly simplifies the entire approval process and also facilitates the management of evidence.

Here are the advantages of using the digitalized PPA process steps through the use of material.one

material.one advantages

Summary and conclusion:

The implementation of material.one in the production process and product release (PPA) for series release plays a decisive role in ensuring a punctual and cost-efficient start of production (SoP). By digitizing and automating the sampling process with material.one, not only are the planning phases significantly shortened, but the costs for the process are also considerably reduced.

This platform minimizes the possibility of errors and improves data quality, leading to faster and more accurate decision-making in the approval process. The real-time traceability of inspection results enables an immediate response to any problems, which in turn helps to avoid delays and thus meet the planned production start.

The dissolution of process and company boundaries by material.one and the end-to-end integration of company processes into the supply network make a significant contribution to increasing efficiency. This means that adjustments and changes in the series release process can be made quickly and efficiently, which in turn supports compliance with the SoP schedule.

The reuse of documents and data for new start-ups or changes is another important aspect that saves costs and speeds up the process. Savings of around 50% in working time for specialist staff not only increases productivity, but also reduces the overall costs of the approval process.

In summary, material.one enables a more efficient, cost-effective and timely preparation and execution of the production start. Companies that digitize their PPA processes for series release with material.one are thus taking an important step towards an optimized, cost-efficient and punctual start of production. Further details can be found in the study "Potentials of digital sampling" .

Read more articles

Our articles offer quality, production and laboratory managers valuable insights to successfully drive the digital transformation within their companies.

Learn more about material.one

With material.one all stakeholders can collaborate a standardized manner in a compliance conforming way based on the "need to know". As an industry cloud platform, material.one provides information on material and material sampling, percentage of recycled material, certificates as well as CO₂ footprint information.