Supply chain law: actions for digital sustainability management

An overview of the Supply Chain Act and how you can use digitization solutions to meet the requirements of the Supply Chain Act in a secure and forward-looking way.

Ecological overexploitation is reaching threatening proportions worldwide and is continuing to rise rapidly. Child labor also continues to increase annually (160 million children according to UNICEF) and other major problems such as pay inequity and forced labor, must be combated more strongly worldwide. Therefore, The Supply Chain Act was passed in December 2022 and was put into force on January 1, 2023. The new Supply Chain Act in Germany and Europe obligates companies to act fairly and sustainably in their supply chain. In May, the EU is to follow up with further, stricter regulations. The UK and the EU have been calling for stricter uniform laws in this area for several years and have already introduced initial regulations, for example with the "EU Green Claims Directive" and “UK Green Claims Code” anti-greenwashing legislation.

What needs to be considered and to which companies does the Supply Chain Act even? Below we have listed the most important facts about the German and European Supply Chain Act.

Origin and definition: German Supply Chain Act

The Act on Corporate Due Diligence Obligations in Supply Chains passed in the German Parliament will initially only apply to companies with 3,000 or more employees and a registered office or branch in Germany from 01.01.2023. From 2024 on, the law will additionally come into force for companies with 1,000 or more employees. However, smaller companies will also be indirectly affected if they are confronted with contractual changes in the future. Whether companies are directly and indirectly affected, it is equally important to know what is in store for them and what the Supply Chain Act specifically stipulates. Also, to be able to assess whether the changes required of partner companies are appropriate. The Act establishes due diligence, environmental obligations and regulatory enforcement that cover direct suppliers. The regulations listed below are required by law:

Companies must introduce a so-called due diligence system that regularly checks whether environmental destruction or human rights violations occur in supply chains through direct suppliers.

Companies must take measures to prevent or remedy such violations.

Companies must make their due diligence systems and measures publicly transparent.

The official enforcement obligation regulates controls and possible sanctions (for example fines) in this regard. Fines can be based on the total turnover of a company (from EUR 400 million annual turnover) as well as the severity of the offenses. It is even possible to be excluded from public contracts if the fine exceeds EUR 175,000.

Origin and definition: European Supply Chain Act

As early as December 2020, all 27 member states were in favor of a European Corporate Sustainability Due Diligence. In February 2022, the EU Commission presented its draft and afterwards the draft was adopted by the European Council in December 2022; the next step is for the European Parliament to agree on a position, which is expected to happen in May 2023. After that, EU member states will have two years to transpose the instructions into national laws. But what specific instructions should the European supply chain law now contain for companies? In order to protect human rights and the environment, and also to combat forced labor and child labor, the law will obligate EU companies to comply with the following regulations in the future:

Companies must check themselves and their global suppliers, including all direct and indirect business partners, for malpractice.

Due diligence requirements in the management processes, complaint possibilities for every person throughout the supply chain and also regular reports (in the form of an annual report for example) should make environmental destruction and exploitation disappear from the global supply chains of EU companies.

To whom does the European Supply Chain Act apply?

In order to be affected by the regulations of the law, the legal structure of the company is the first determining factor. The European Supply Chain Act applies to the following companies:

The European Directive on corporate sustainability due diligence is to apply to corporations, limited joint-stock partnerships, limited liability companies and also regulated financial companies and insurance companies.

All EU companies and also companies from third countries operating in the EU with one of the aforementioned legal forms that have a net annual turnover of more than 150 million euros and employ more than 500 people are obligated.

The exception here are so-called focus industries that entail a particularly high risk potential for the environment or people (i.e. agriculture, textile industry, or mining). Here, the law becomes applicable to companies with at least 40 million euros in net annual sales and more than 250 employees. For these companies, however, the regulations start to apply two years later.

With the European Directive on corporate sustainability due diligence as with the German Act on Corporate Due Diligence Obligations in Supply Chains, small and medium-sized enterprises (SMEs) may also be indirectly affected by the regulations (as suppliers for example).

Differences in German and European supply chain law

As soon as the European supply chain law also comes into force, the EU member states must transpose the directives into national laws within two years. Germany will therefore have to tighten up its supply chain law, which has been in force since January 2023. Below you will find the most important differences between the German and the European supply chain law:

The European law provides for civil liability for companies. This means that those affected can sue for damages before European courts.

The German law only applies when companies have more than 3000 employees (from 2024 from more than 1000 employees). The European law, on the other hand, applies when companies have more than 250 or 500 employees.

In contrast to the European law, the German law only obligates the inspection of direct suppliers. The European law for supply chains, on the other hand, obliges verification of the entire supply chain.

Due diligence for companies

Companies to which the German or European Supply Chain Act applies have an obligation to fulfill their corporate due diligence to comply with the regulations - and also to monitor those of suppliers or those of business partners. In order to meet this due diligence obligation, there are a number of requirements, some of which can have a far-reaching impact on business operations processes:

Complaint procedures must be established that can be used by anyone throughout the supply chain.

Due diligence obligations must be integrated into management processes and systems. These must be made an integral part of corporate policy.

A regular, transparent, and public report (for example an annual report) must be produced to track due diligence.

Companies are required to analyze negative impacts on the environment and people throughout the supply chain themselves and to monitor the effectiveness of the measures.

Potential negative impacts must be actively prevented or mitigated.

Existing negative effects must be eliminated or reduced to a minimum.

Note: In the Directive on corporate sustainability due diligence, there is an important special provision for companies with an annual turnover of more than 150 million euros and more than 500 employees: these must also reconcile their business activities and corporate objectives with the 1.5 degree target of the Paris Agreement.

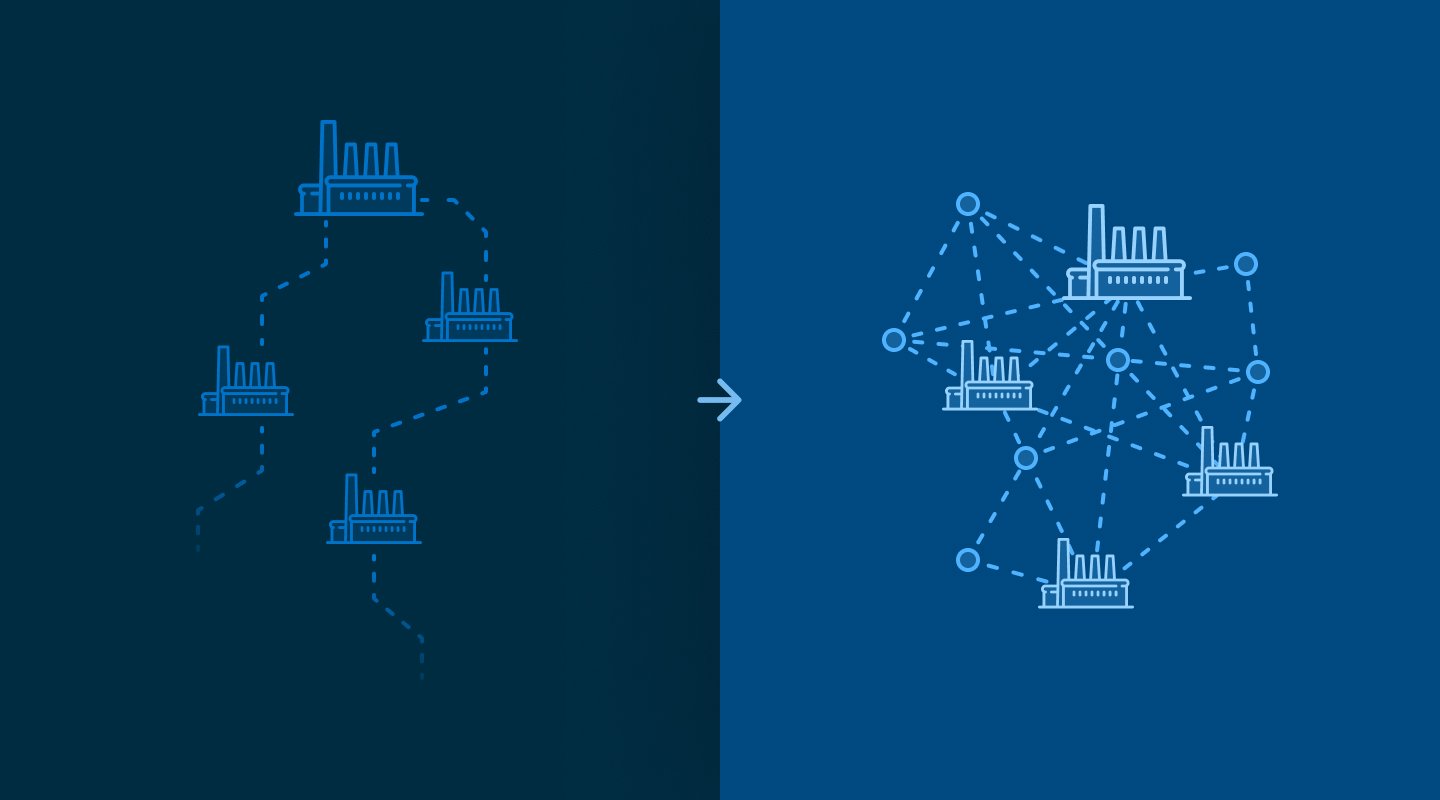

Challenge: Classic supply chain becomes a digital delivery network

Developing a meaningful analysis and effective risk management for compliance with all regulations throughout the entire supply chain can be an enormous challenge, especially for companies in complex industries or with many business partners in supply chains. Individual processes in different parts of a supply chain also make analysis even more difficult. Digitization solutions can aid in business models like this by enabling fast communication and collaboration between parties within a network. Information and process silos are thus dismantled, transparency is promoted, and data can be exchanged in real time.

In the future, it will be particularly important to monitor and evaluate a large amount of data when checking suppliers and vendors, and to provide, exchange and combine this data between all the parties involved in the supply chain. The previous classic form of a supply chain with many different parties and interests will therefore continuously evolve into a complex supply networkin the future. One in which sustainability and transparency will take center stage. The regular monitoring and control of the supply network can be centrally implemented with digital solutions from adesso, urban energy and material.one as well as other partners.

Benefits of a digital solution for supply chain compliance

As compliance with supply chain laws can become a challenge for companies, they should consider using a digitization solution in order to gain advantages in the implementation of analyses and measures. Below are examples of benefits that digitization solutions bring to supply chain management and manufacturing:

Analyses and measures can be created, assigned and checked automatically.

Permanent and complete transparency for evidence and compliance with standards can be ensured.

Damage to company image and fines can be avoided through regular audits.

Defects from suppliers and subcontractors can be categorized and detected at an early stage.

Further reports on business goals can be created (i.e. cost efficiency).

adesso and material.one with digital solutions for a sustainable supply chain

With digital service solutions from material.one and adesso, you have the opportunity to map and network all parties involved in your entire supply and value chain and to automatically exchange valuable data between the parties. Modern technologies such as data analytics, digital control platforms, and AI make it easier to implement required standards on supply chain due diligence. Benefit from the features of our digital service solution for the exchange of data in the supply network.

-

Our software solution is optimally tailored to your industry requirements and seamlessly integrated (incl. SAP connection). Customer-specific requirements can be stored.

-

Regular monitoring and early detection of potential policy violations according to preset criteria or specifications.

-

Necessary information (i.e. production sites, interfaces to ERP systems, supplier master data) of all partners and suppliers is centrally compiled, stored and documented in one system.

-

Secure exchange of data within a network with many suppliers. Standards, specifications or even current test results (e.g. laboratory results) are transmitted quickly and digitally to all parties in the supply chain.

-

Easy onboarding and approval of new suppliers in the network. All participants in the supply chain receive the required access and authorizations.

-

A code of conduct and new guidelines can be provided via online platform. Corrective actions can also be quickly communicated and implemented.

-

Performance reviews and audits for regions, raw materials groups or companies can be created. These can be sorted according to needs, deadlines or guidelines (for example Fair Wave or BSCI).

-

Digital transmission of predefined questionnaires or forms for self-disclosure from suppliers and vendors.

-

No or fewer media disruptions and manual steps (e.g., e-mails) due to a uniform system in the supply chain.

Guide for your company to the Supply Chain Act

In order to comply with the Supply Chain Act obligations, you will find an overview and checklist below. This will help you to adapt your procurement processes and dealings with your suppliers to the newly applicable regulations. Additionally, appointing a supply chain officer to coordinate and control the implementation and monitoring of measures should be considered.

Create transparency in the supply chain

As a basic prerequisite for all analyses, processes and measures, the creation of a transparent overview of the initial situation should have top priority. Get an overview of all companies involved in the supply chain and their activities. Identify, consolidate, and sort all processes within your supply chain (using the D-U-N-S number is a possibility). Assign all data to the respective suppliers and supplement the consolidated data with further information on the companies involved (i.e. proofs, releases, purchasing volumes).

Supply chain risk analysis

Once an overview of all processes, suppliers and vendors has been created, a comprehensive analysis and risk assessment should take place in relation to Supply Chain Act requirements (i.e. Is compensation equitable? Is there evidence of child labor? What are the working conditions and are workers' rights being violated?). Also establish a risk management system that regularly defines concrete measures to prevent new risks. With digital solutions such as those from material.one or adesso, these risk analyses can be created automatically based on data and checked regularly. This not only provides you with a very precise overview of all regional risks and participating companies in the supply chain, but also allows you to be regularly informed about newly added risks. Of course, you can also use the collected data and reports for compliance with other guidelines (like industrial waste) or even derive further measures for the implementation of your corporate goals and potentials for cost reduction.

Measures and implementation

In the final step - and also on an ongoing basis after regular analysis - the right measures for compliance with supply chain laws should be derived and implemented. The following measures should always be considered after the analysis:

Create standardized questionnaires and audits for supplier self-disclosures.

Verify that you can provide all the resources needed within the company to comply with the new obligations and make them available.

Determine how to establish a goal-oriented complaint procedure within the company and throughout the supply chain.

Work out guidelines within the company on how the Supply Chain Act must be taken into account in individual procurement steps.

Plan ahead for where conflicting goals may arise in your business processes and requirements. Determine possible corrective measures when such conflicts are found.

Additionally, explore whether a change or extension to your compliance policy may also be needed.

Create a policy statement that commits all contract participants to respect human rights in all types of business activity.

It is recommendable that successful measures also be incorporated directly into contractual supplier relationships or into award processes as standard. In this way costs can be reduced in the long term through control processes, subsequent measures, and finding new suppliers. It can also reduce the general risk of non-compliance with laws and fines.

Conclusion

In the future, German and European companies will have to monitor their supply chains very carefully and comply with new standards to safeguard human rights and protect the environment. throughout the supply chain companies will have to develop a concrete plan to minimize global human rights violations - a major challenge with a large amount of data to monitor. It is therefore becoming increasingly important for companies to ensure a supply chain that is preventive, transparent, automated and data-driven, which can not only ensure sustainability and environmental protection, but above all, remain successful and profitable in the process. As a service company for IT consulting, with experts from the fields of development, logistics as well as security and also with our individual software solutions from material.one and adesso, we enable you to combine these goals in a future-oriented way. Do you need consulting or support for the implementation of the Act on Corporate Due Diligence Obligations in Supply Chains in your company? Feel free to contact us for a consultation or to request further information. We are happy to learn more about your upcoming challenges and support you in the implementation of compliance measures related to the Act on Corporate Due Diligence Obligations in Supply Chains or even holistically in the digitalization of your supply chain.

Read more articles

Our articles offer quality, production and laboratory managers valuable insights to successfully drive the digital transformation within their companies.

Learn more about material.one

With material.one all stakeholders can collaborate a standardized manner in a compliance conforming way based on the "need to know". As an industry cloud platform, material.one provides information on material and material sampling, percentage of recycled material, certificates as well as CO₂ footprint information.